- Correct windows assembly will significantly extend their life-span.

- Fitters should disconnect sashes and mount the frame first to facilitate easy assembly.

- Assembly clearance must be at least 10 mm per one side.

- After the frame is placed on the window seal, you must level the frame in horizontal and vertical position and properly fix it using wooden wedges.

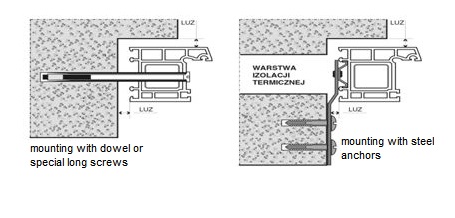

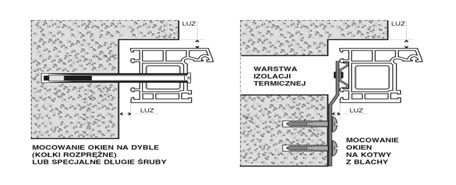

- Windows should be mounted with the use of rawplugs, the so called Æ10 dowels, or mounting anchors.

- Once the frame is fixed, you should mount and properly adjust the sashes.

- Then, insulate the window by filling the space between the frame and a wall with polyurethane foam. It is recommended to moisten the space between the frame and the wall prior to sealing it with foam. After the foam stiffens, remove the wedges and additionally fill in empty places with the foam. Fitting foam is an insulation material only, therefore it is not allowed to use it as a single bonding material connecting the window with the wall.

- Lower horizontal elements of frames and sashes are fitted with special grooves for precipitation water drainage, which should not be covered.

- During the mounting process, you should remember that external and internal sill properly sealed with silicone is the final element of a new window.

+48 91 4321 321

+48 91 4321 321  +48 533 315 977-RYNEK: DE, AT, CH

+48 533 315 977-RYNEK: DE, AT, CH +48 533 315 972-RYNEK: SE,NO,DK,BE,NL,UK

+48 533 315 972-RYNEK: SE,NO,DK,BE,NL,UK